Expansion Joints

Expansion Joints have many uses, including: Relieving system strain, absorbing movement, compensating for misalignment in a system, reducing mechanical noise, and eliminating electrolysis between dissimilar metals.

GHX nonmetallic expansion joints and flexible couplings are an ideal solution for a wide range of industries, including chemical and industrial process piping, pulp and paper manufacturing, power generation, waste water and sewage disposal, HVAC, as well as marine applications.

GHX rubber expansion joints are used for the same reason as their metallic counterparts. Rubber, in this case, can refer to many different compounds, such as Butyl, Viton, Neoprene, EPDM, all materials designed to operate optimally in many different environments. Spool type rubber joints can be manufactured to over 10 feet in diameter, and GHX rubber expansion joints and couplings are ideal for industries and applications such as power generating stations, pulp and paper manufacturing, chemical and industrial process piping, wastewater and sewage disposal, HVAC and marine applications.

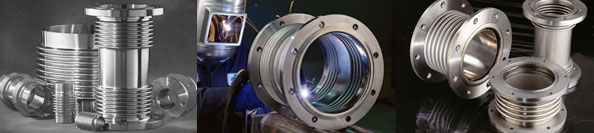

GHX metal expansion joints are designed, engineered and furnished by experienced manufacturers with years of experience. Produced in standard pipe sizes 2 through 48 inches, the bellows can be fabricated with fixed or floating flange pipe weld ends, or plate flange, depending on your needs. The bellows can be manufactured from type 321 stainless steel, monel, 316 stainless steel, and aluminum and titanium can also be used for special cases. In addition, liners are also available.

We can provide a variety of joint types and sizes to provide movement in an axial, angular or lateral direction, whatever the job requires.

GHX flue duct expansion joints are used for lightweight jobs, such as scrubbers, precipitators, bathhouses, and fans in air handling systems. Available in round, rectangular and square configurations, as belt (unflanged) or U-type (flanged), they can be manufactured with virtually no size restrictions. Please contact a representative for specific specs.

GHX is committed to providing you and your company with the right kind of expansion joint for the job you need to get done, and to provide it with a maximum of customer service and attention to detail, ensuring both maximum efficiency and safety.

Let's Talk

Let GHX experts answer your questions or get you started with a quote for your project.

Careers @ GHX

Are you ready for new challenges and new opportunities? Join our team!

Current OpeningsStay informed of GHX news & promotions by signing up for our newsletter, delivered straight to your inbox.